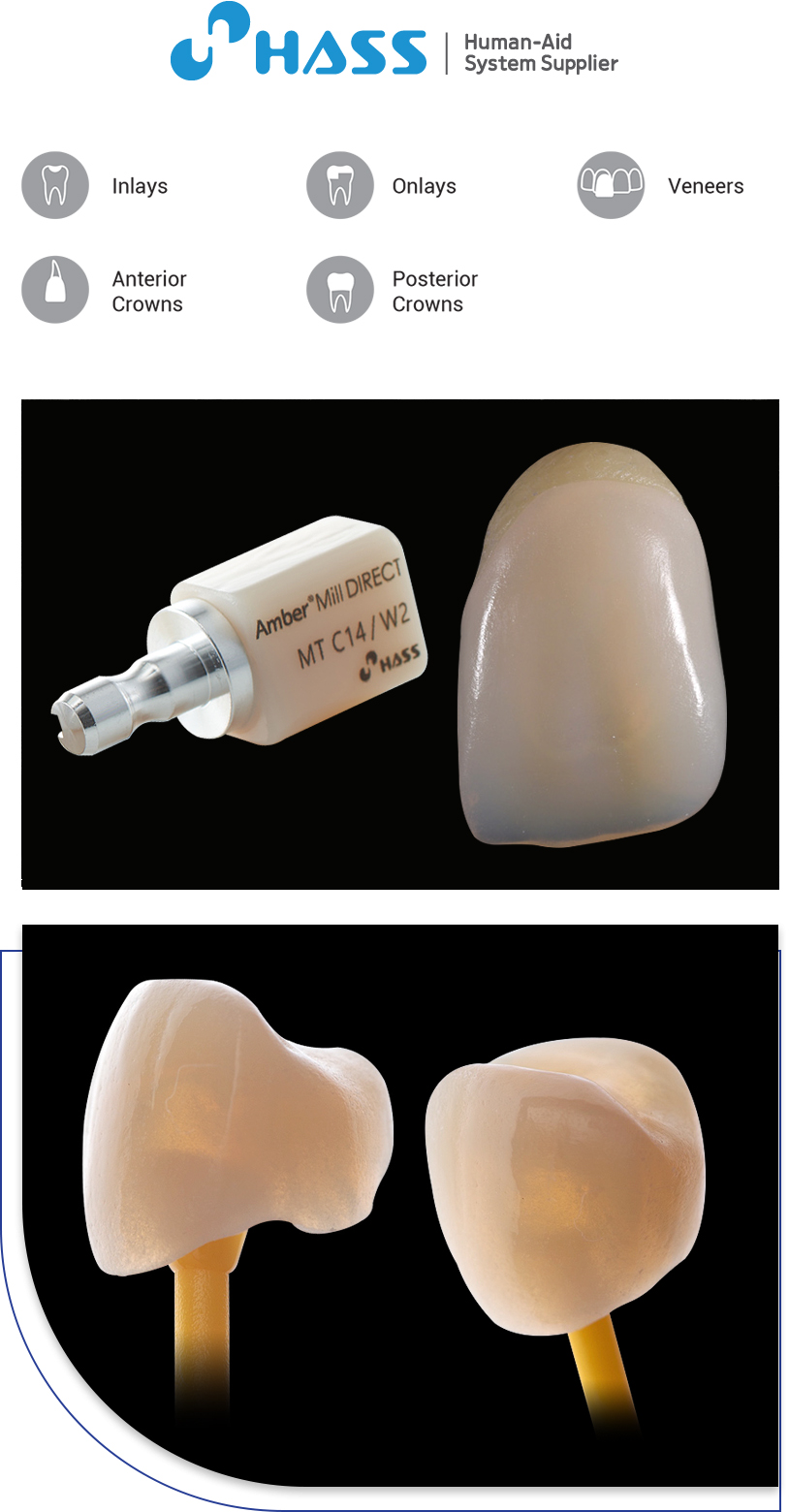

Amber® Mill Direct is a pre-crystallized lithium disilicate, requiring no additional oven curing. Simply mill, polish and place. Save considerable time – with every restoration.

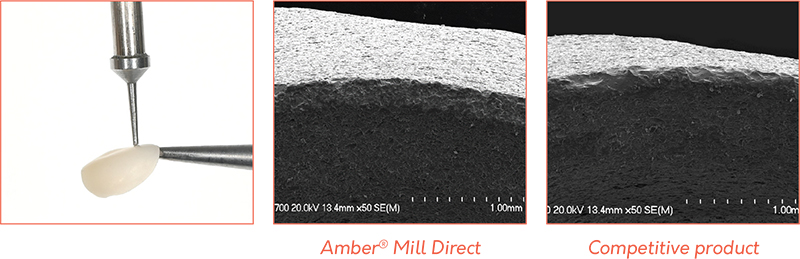

The unique structure of Amber® Mill Direct produces the smoothest margins.

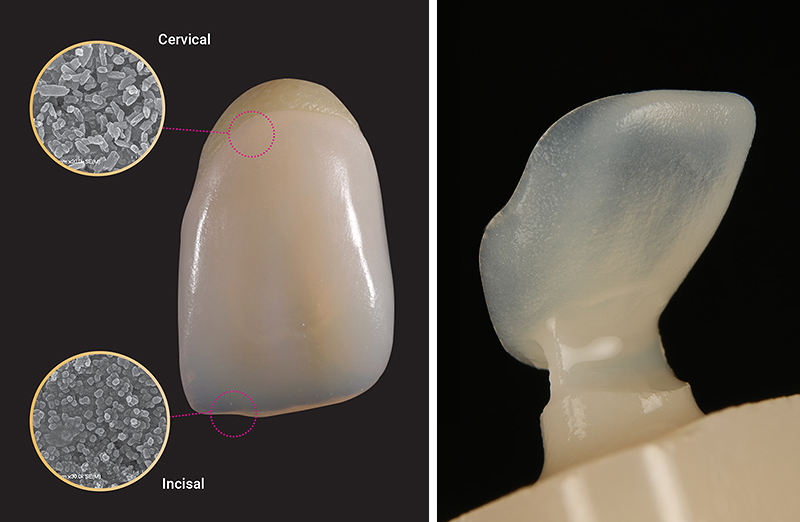

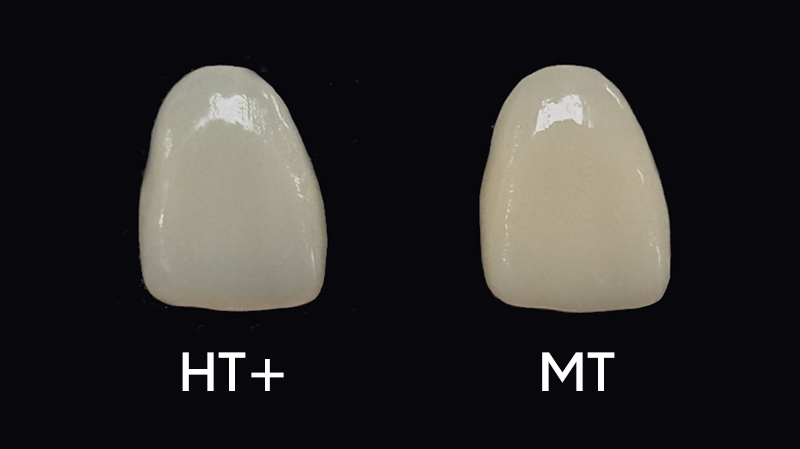

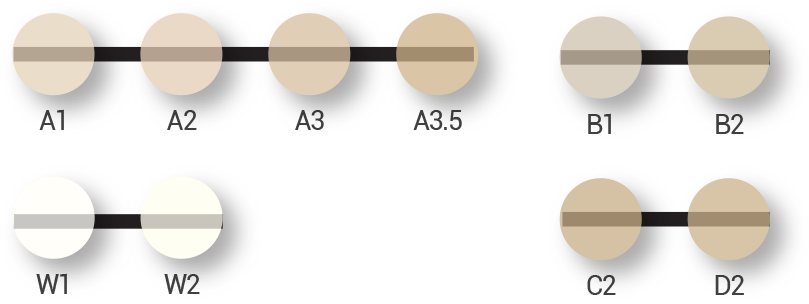

Amber® Mill Direct achieves natural translucency by applying a gradated microstructure, from the cervical to incisal/occlusal regions, without additional characterization.

SAVE CHAIR TIME! NO CRYSTALLIZATION REQUIRED.

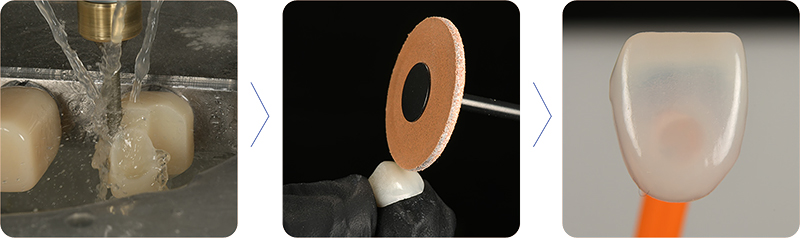

Just mill and polish. To expedite the in-office fabrication process, Amber Mill® Direct does not require crystallization. After milling, you can polish and deliver the restoration directly to the patient. Achieve excellent esthetic results with our gradated translucency without any firing.

ESTHETICALLY CHARACTERIZED RESTORATIONS.

If your restoration requires more characterization, simply stain/glaze to achieve better esthetic results.

(Glaze Recommended Temperature Range: 780°C or below)

(Glaze Recommended Temperature Range: 780°C or below)

|

|

|

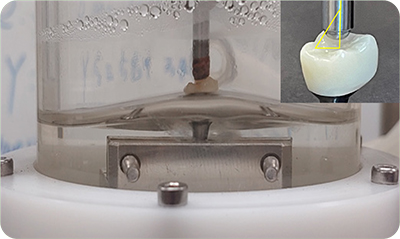

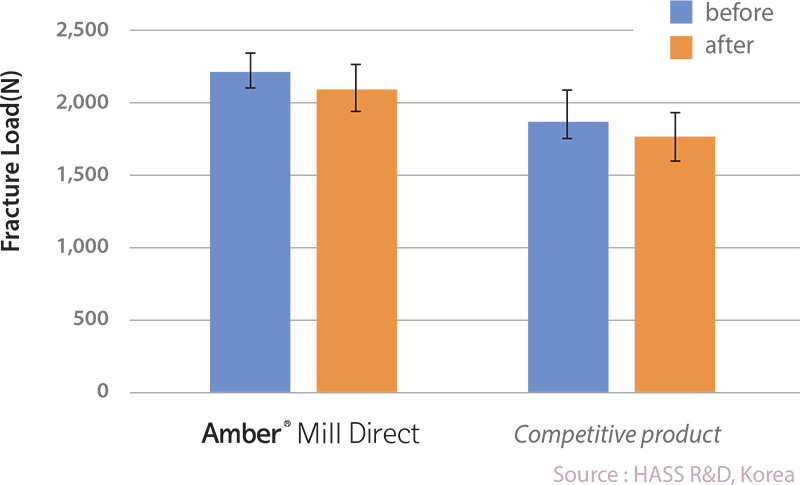

1,000,000 cycles / 1.5 Hz / 10kg force (in pH 7.2 Water) and thermal cycling at 5-55 °C for 30s each |

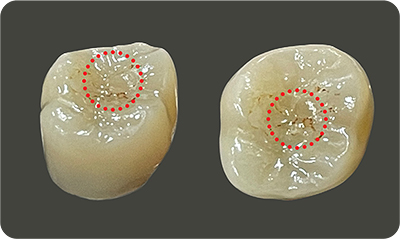

Test result from Chewing simulator proves superior wear-out resistance in occlusal region |

|

Size |

Dimensions (mm) | Pcs / Pack |

|

C14 |

14 x 12 x 18 | 5 blocks |

Amber Mill Direct – No oven, no wait milling blocks (0.34 min)

Amber Mill Direct – Step by Step procedure video (4:26 min.)

(Felt wheel included)

Perfect companion to Amber® Mill Direct blocks.