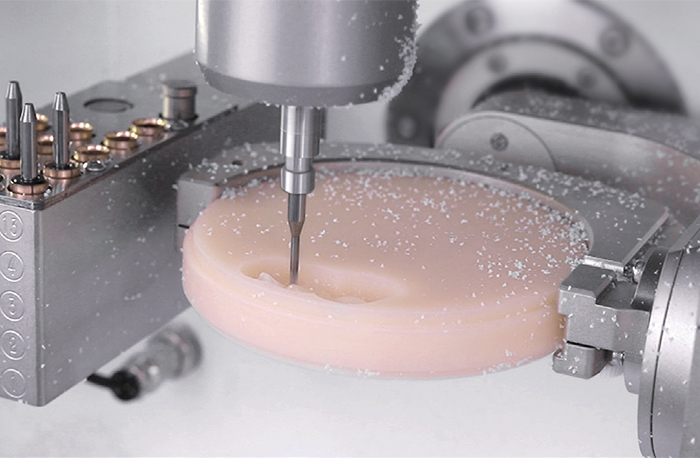

Stable milling with precision down to the micron. The full servo drive system precisely compensates for minor vibrations during the milling process, ensuring stable, efficient, and continuous production around the clock. It achieves precision machining, perfectly handling even the most complex restoration.

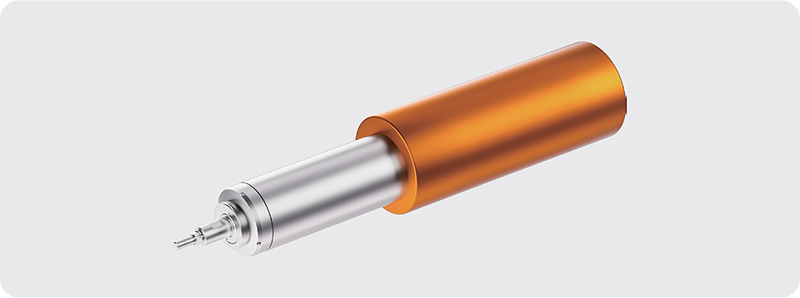

Featuring a German 60,000rpm high-power electric spindle, P55D offers reliable performance for milling complex cases and hard materials. Its compressed air-free design streamlines operations—Simply plug and mill.

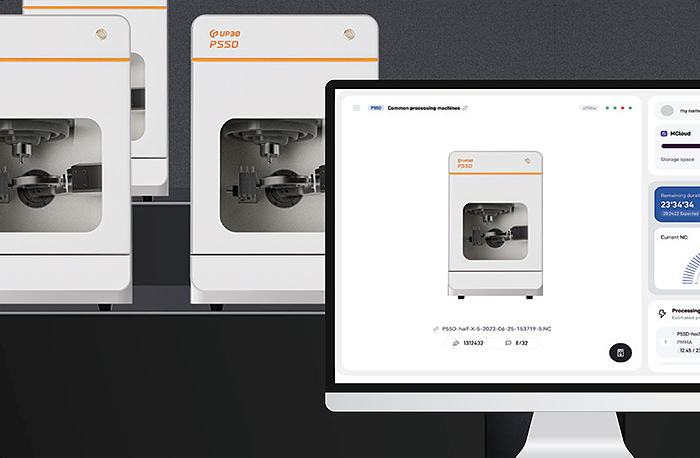

Utilize MillMind app for smart remote control, coupled with smart milling alerts and tool life monitoring. This reduces downtime and significantly enhances efficiency, making the workflow more effective.

Supports a variety of popular materials such as zirconia, wax, PMMA, PEEK, composite resin and soft metals. Compatible with both disc and block formats, it offers custom-tailored, efficient restoration solutions to meet the needs of diverse cases.

Equipped with a custom 0.3mm micro-carving milling cutter and a 0.6mm extended milling cutter, P55D achieves precise milling of facial details, producing restorations that closely resemble natural teeth.

Perfectly recreate the detailed contours of teeth with 90-degree vertical milling. This method precisely machines textures on the labial (or buccal) sides, reducing handmade processing time and ensuring optimal results.

Featuring an all-in-one silicone seal for dustproofing, this design effectively prevents dust intrusion into the machine, reducing component wear and maintenance needs, and significantly enhancing longevity.

A larger milling chamber provides operators with more space and flexibility, enhancing the material handling and removal experience, and effectively increasing work efficiency.

P55D features a high-concentration ionizer that neutralizes static in resin debris like PMMA, simplifying cleanup and enhancing efficiency. No need for costly accessories such as air tools, cutting down on both initial and maintenance costs.

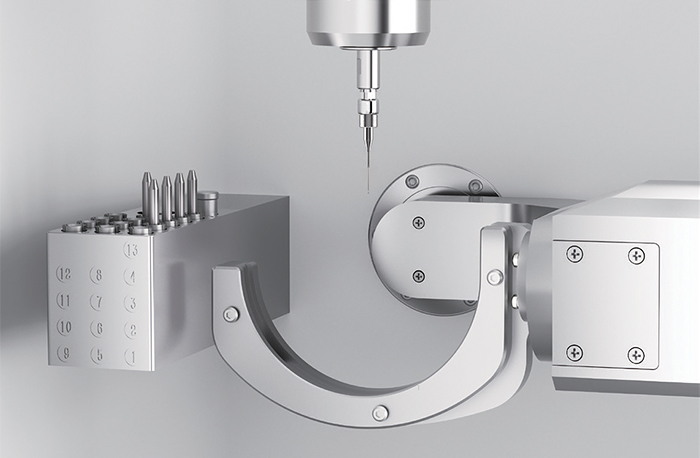

The C clamp design provides expanded space for buccal side milling of restorations, significantly improving material layout and edge utilization to ensure efficient use of materials.

The exterior LED bar syncs in real-time with the machine to display processing progress and status, effectively reducing the need for manual checks and enhancing production efficiency.

The advanced CNC-3 software controls multiple processing units simultaneously, monitoring and managing several machines in real-time, saving desktop space and reducing computer resource wastage.

Wave goodbye to sudden interruptions; our software automatically resumes milling from the last stop, avoiding redundent processing and improving work efficiency by at least 80%.

One-click smart calibration simplifies operations and automatically optimizes precision, ensuring the accuracy and stability of the equipment, minimizing milling errors, and saving materials to enhance efficiency.

| Fields of Application | Dry machining |

| Materials | Zirconia,wax,PMMA,PEEK,composite resin,soft milling CoCr sintering metal |

| Material Specifications | Discs: height 10-30mm, diameter 98.5mm Blocks up to 40x20x20mm (Max) |

| Indications |

Coping, Full Crown, Full Crown Bridge, Screw-Retained Crown, Inlay, Onlay, Veneer, Post and Core, Removable Partial Denture (RPD) Framework, Implant Bridge, Full Denture, Bite Splint, Superstructure over Bar, Esthetic Aligner, Model |

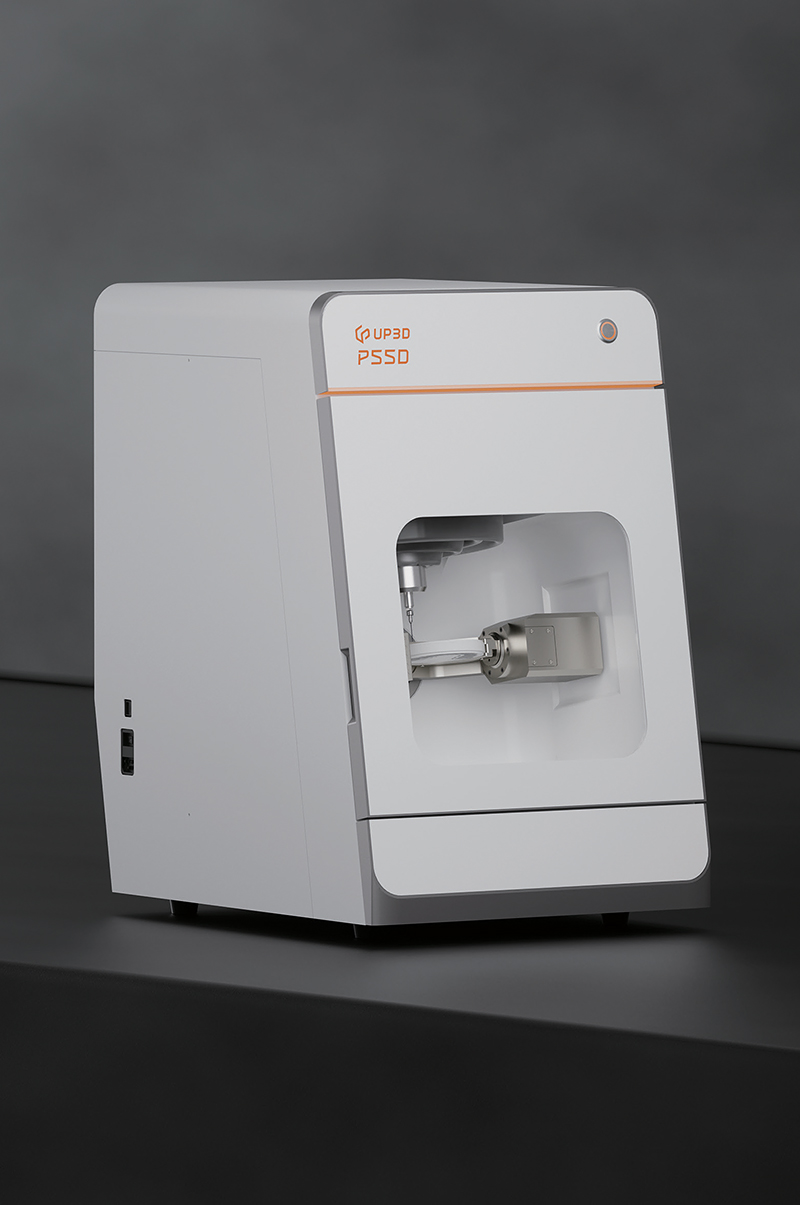

| Dimensions | 445 x 595 x 704mm |

| Weight | 106kg |

| Construction | Machine bed made of solid cast aluminum body |

| Number of Axes | 5-axis |

| Housing | Steel, white high-gloss lacquer finish, main front housing: injection-molded |

| Linear Axes (X/Y/Z) | Precision ball screw drive; Travel: 104x60x100mm |

| Rotary Axes (A/B) | A-axis: 360°; B-axis: ±33° |

| Control Unit | 5-axis precision full servo drive system |

| Lighting | LED lighting inside the working chamber, with additional status indication |

| Power | 750W |

| General | High-frequency spindle, automatic tool change, no air cooling required |

| Speed | Up to 60,000 rpm |

| Tool Holding Diameter | Ø4.0mm |

| Power | Max. 0.8KW |

| Tool Change | Tool magazine for 13 tools, length measurement and tool breakage monitoring via precision measuring key |

| Voltage | 220±10%V AC 50/60 Hz |

| Dust Extraction | Filter level: M; Flow rate: 2500L/min |

| Data | Wi-fi, USB, Ethernet port |

| Operating Temperature | Between 5 °C and 40 °C |

| Air Moisture | Below 80% (relative), non-condensing |