The P42 PLUS is fully integrated into the Soreal same-day restoration system—empowering clinics to complete restorations in one visit. With the UP610 intraoral scanner, intuitive Soreal CAD/CAM software, and the plug-and-play P42 PLUS milling unit, the full workflow becomes faster, cleaner, and easier for clinicians and patients alike.

Single-unit anterior restorations can be milled in as little as 15 minutes, while molars are typically completed within 25 minutes—allowing efficient, high-quality, and cost-effective chairside treatment.

UP610 intraoral scanner

Soreal software

P42 PLUS milling machine

F30 Porcelain Furnace

P42 PLUS is built to make wet milling simpler, cleaner, and more efficient—without compromising performance.

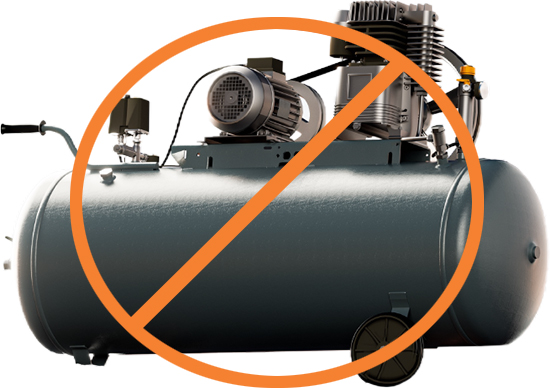

With no external air compressor required, installation is truly plug-and-play. Whether it’s a small lab bench or a clinic corner, P42 PLUS fits right in.

It’s optimized for high-quality milling of glass ceramics, PMMA, and composite resin—perfect for crowns, copings, inlays, onlays, and more.

And whether you’re handling one case or batching several a day, it delivers the speed, accuracy, and reliability your workflow depends on.

Traditional wet mills rely on bulky, noisy external compressors. P42 PLUS eliminates the need for one.

It runs quieter, installs easier, and takes up less space. Fewer components mean lower maintenance and more flexibility in your workspace.

1 – Plug & Play

|

2 – Easy to Use

|

3 – Fully Compatible

|

4 – High-Performance

|

5 – Efficient & Affordable

|

*Milling times are based on laboratory tests. Actual results may vary depending on restoration size and complexity. |

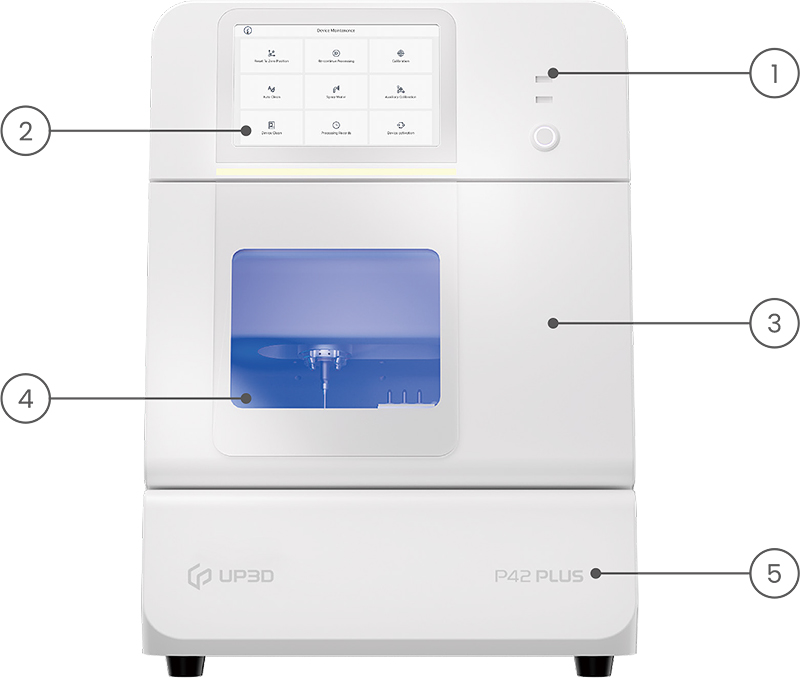

P42 PLUS combines a cast monoblock frame with high-precision motion components and an intelligent cooling system. The result: ultra-stable performance, even for demanding materials and delicate restorations.

A high-definition internal camera gives you real-time visual access to the milling chamber. Ideal for remote troubleshooting and quality control, it helps you stay in control—improving uptime and reducing workflow interruptions.

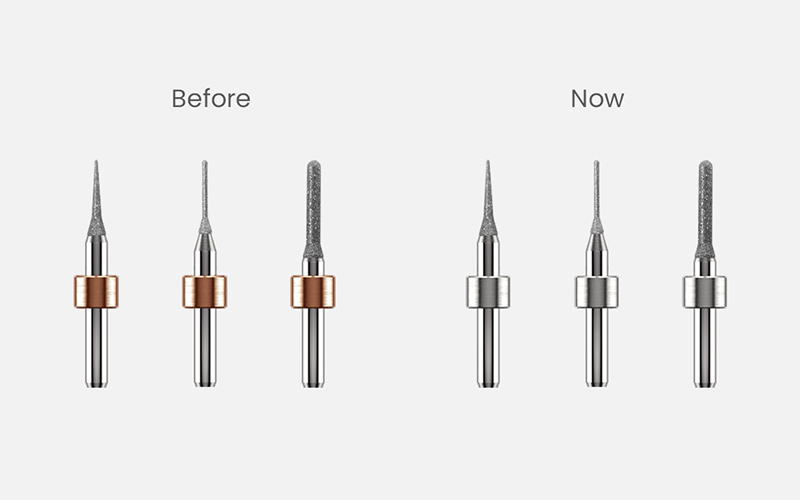

The burs designed for glass ceramic milling now feature a finer, more uniform diamond coating. This reduces edge chipping, improves margin smoothness, and enhances surface quality—especially on fragile materials.

Clean, Cost-Effective, Eco-Friendly

The P42 PLUS’s innovative pure water milling technology ensures no additives are required, maintaining material integrity and reducing waste. This easy-to-manage solution not only simplifies maintenance but also lowers operational costs, giving your lab a reliable and cost-effective milling option for consistent performance.

No More Complex Manual Grinding

Equipped with a ±20° A-axis, P42 PLUS enables accurate undercut milling for complex restorations. When combined with UPCAM’s smart nesting algorithms, it removes the need for manual grinding—resulting in better fitting restorations, and less rework.

Maximize Material Utilization and Output

P42 PLUS supports dual veneer nesting on a single ceramic block, allowing you to process multiple restorations in one go. This smart nesting minimizes material waste and maximizes output—ideal for busy labs looking to cut costs without cutting quality.

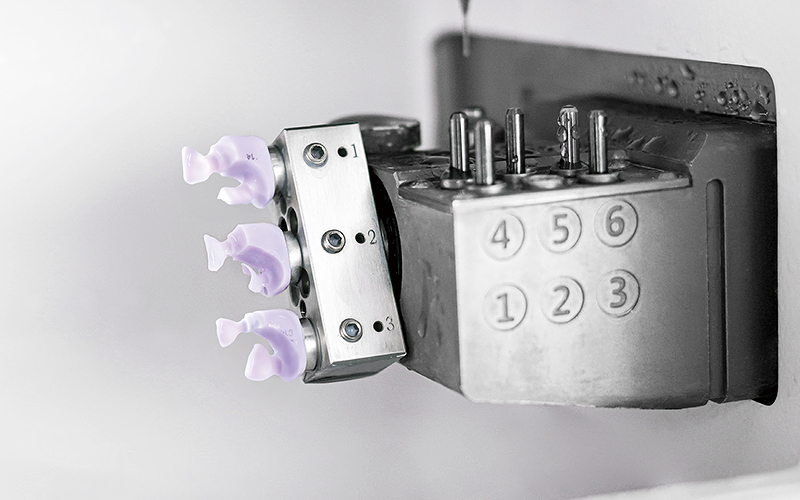

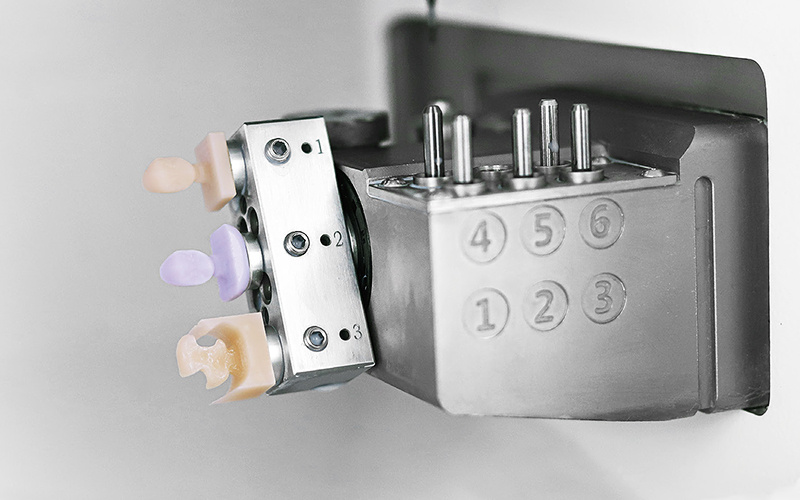

Handles up to three different material sizes at once, thanks to its precision-engineered processing capability. This innovative feature dramatically boosts production efficiency and adapts to diverse needs across dental labs and practice labs.

| Fields of Application | Wet machining |

| Materials | Glass ceramics, titanium, composite resin, PMMA |

| Material Specifications | Blocks up to 40x20x20mm (Max) |

| Indications | Full Crown, Full Crown Bridge, Screw-Retained Crown, Inlay, Onlay, Veneer, Customized Abutment |

| Dimensions | 564 x 402 x 564 (mm) |

| Weight | 80kg |

| Construction | Machine bed made of solid cast aluminum body |

| Number of Axes | 4-axis |

| Rotary Axes (A/B) | A-axis: 360° |

| Lighting | LED lighting inside the working chamber |

| General | High-frequency spindle, automatic tool change, no air cooling required |

| Speed | 60,000 rpm (max) |

| Tool Holding Diameter | Ø4.0mm |

| Power | Peak power (Pmax): 800 watts • continuous power (S1): 450 watts |

| Tool Change | Tool magazine for 6 tools, length measurement and tool breakage monitoring via precision measuring key |

| Voltage | AC 100V-240V, 50~60Hz |

| Data | Wi-fi, USB, Ethernet port |

| Operating Temperature | Between 5 °C and 40 °C |

| Air Moisture | Below 80% (relative), non-condensing |

| CAM Software | UPCAM |